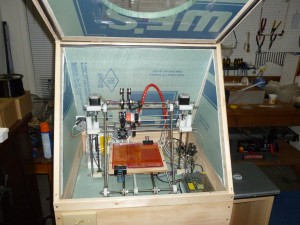

My 3D printer lives in the garage. I use it to print ABS plastic, so the smell needs to be out there. However, as my garage is unheated, I have problems with ABS prints warping and cracking, especially during the winter due to the cold air around the part as it is printed. To solve this problem (and get better performance even in the summer) I built an insulated cover for my 3D printer.

I cut a round viewport in the door that is covered by shrink fit window insulation plastic. I’m in the process of adding a Raspberry Pi with a camera using OctoPrint inside the case to enable remote printing/management, but I’m not yet ready to have a completely enclosed printer (and even when I get the webcam set up, I think having a viewport will still be useful). If you want to cut a nice circle into foam, I recommend the following technique: 1. Drill a hole where you want your circle to be centered. 2. Push a bolt through the hole, and clamp the end of the bolt in a vise such that the foam is free to rotate against the edge of the table. 3. Clamp a hand-held hot foam cutter sticking off of the table through the foam at the right radius for your circle and power it up. 4. Rotate the foam until your circle is cut out.

I used 1×2″ furring strips for the triangular frame, with 3/4″ foam insulation for the walls. The entire top cover can lift right off the plywood box that serves as my printer base, and weights well under 10 lbs. I used caulk to hold the insulation to the frame (and block air movement). I also used thin foam weatherstripping around the edge of the door to make it more airtight. In this picture (shot up from the bottom while the triangle was laying down on the ground) you can also see the shrink fit window plastic on the back side of the porthole.

After turning on my heated build platform (plus the excess heat from the power supply) for an hour, the interior of my printer enclosure was at 89 degrees (Fahrenheit) [A good 30 degrees warmer than my garage.] I figure once I turn on the filament heater on the extruder for an actual print that will go up another 5 to 10 degrees.

Although not quite as hot as a Stratesys heated build envelope, I’m hoping that the the warmer air and protection from drafts will significantly reduce my warping and cracking issues when printing during cold weather. Even if it gets up to 100 degrees (F) I’m hoping that it won’t be too hot for the stepper motors and control electronics, as they operated just fine in the summer when the garage is easily 85 degrees F.

The cover also has a nice side effect of reducing noise from the printer (although that really wasn’t audible outside of the garage anyways…). It may even slightly reduce the electrical usage of the printer, as the build platform and filament heaters will not have to turn on quite as frequently.