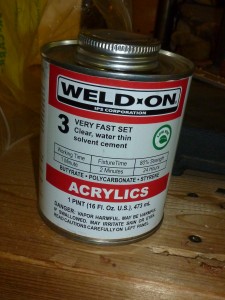

This is an industrial acrylic welding solvent. Highly volatile industrial solvents have the ability to unscrew their own lids and escape into the atmosphere during shipping, so they are shipped inside a sealed metal can. It is assumed that you will have something to “cut this out” when you open the solvent and want to use it.

I’m not going to post a picture of the warnings on the side of the can, because, well, this blog is publicly available on the Internet, possibly read by children, and man, are they scary! Cancer, infertility, death, and skin irritation. Lets just say that when you open this can, your liver pokes you in the side to remind you to put on your nitrile gloves.

So, what am I trying to weld together? Test 1 for my bubble display nozzle options. Well at least one side is made of acrylic….but the other side is Nylon (a 1/8″ ID single barb tube coupling, specifically). I drilled an 1/8″ hole in the acrylic square and the hose barb fit in very nicely for a “flush” fit (with the other side…).

I don’t know if the solvent melted the Nylon……or if the melted acrylic just made a very good friction connection around it, but I couldn’t (easily) pull them apart an hour after cementing. Destructive testing of whatever my final nozzle option turns out to be will be performed after I’m done testing everything, but before I made many many more copies.

The 1 inch square of acrylic will later be cemented to the bottom of a 1 inch square extruded acrylic tube. I will probably fill the area between the acrylic and the square “center” of the coupler with silicon sealant after testing the acrylic-weld-only seal for a few days. After all, if this sucker fails, a floor is going to get wet (or worse…)

Pingback: Acrylic Column #1 (Bubble Display testing) — Jay’s Technical Talk

Pingback: Trying out different nozzle sizes and material — Jay’s Technical Talk

Pingback: Scaling wide to sixty tubes! — Jay’s Technical Talk

Pingback: oneTesla kit review and build comments. — Jay’s Technical Talk