My Curtis 1231C motor controller blew up some MOSFETs and died. I replaced it with a used unit to get my truck back on the road, but now I’m interested in repairing the one that died so that I’ll have a spare.

I might be able to replace the components that died with exact replacement parts (but the IXTH50N20 MOSFETs are hard to find nowadays, and the diodes are basically unobtainable) to get it working, but since I have it open and am doing all of this work, I am exploring alternative (new) components that will have higher ratings and possibly give my controller more capacity or at least more resistance to blowing up again.

Of course, if I replace one component (power switching MOSFET, freewheeling diode, or ripple controlling capacitors), I will probably need to upgrade the other two as well so that I don’t just move the weak link from the MOSFETS to the capacitors or diodes.

Power switching MOSFETS

The original part used is IXYS IXTH50N20, which has a 200 volt maximum rating, 50 amp switching capacity (200 A pulse), and a resistance from source to drain when on Rds(on) of 0.045 ohms (45 micro Ohms). The total gate charge, Qg(on), is 190nC typical 220nC max.

(All packaged in a TO-247 AD case, with drain on the tab connected to the heatsink and Motor – rail.)

An “upgrade” component recommended by David Mosher is the IRFP4668PbF, which retains the 200 volt maximum rating, but has a 130A maximum switching capacity (520A pulse). The Qg(on) is 161nC typical and 241 nC max. This is close to that of the original part, which means that the 4668 won’t turn on much faster or slower than the 50N20’s.

The 4668’s have a much lower Rds(on) of only 0.0097 Ohms (9.7 micro Ohms), which is five times smaller than the 50N20’s. This is good in that it produces less heat (probably 5 times less heat!), but it does have a side effect I would have to work around.

The Curtis logic control board measures the Rds(on) of the MOSFETs under load and uses that as a shunt resistor to detect how much current they are switching. If the Rds(on) of the MOSFETs are lower than the logic board is expecting from the IXTH50N20 parts, the logic board will think the current is much lower than it actually is. This will prevent the controller logic from entering high-current cutback mode unless I can adjust the sensitivity of the current sense circuitry to match the new MOSFET’s value.

The logic board does have a factory set “c/l set” pot, as well as a user adjustable C/L adjust pot, so perhaps by messing with these pots or changing out a resistor I can keep the current sense circuit happy, but it will mean that I will need a way to accurately measure the current in a high power situation, which probably means testing it in my truck….

I like the possibility of making less heat, because a cooler running controller is good for reliability. I also like the fact that the amp rating is much higher, which will make them less likely to blow up, and possibly give me greater performance (if I’m brave and foolhardy enough to make use of it). I don’t like the fact that the maximum voltage rating is still 200 volts. It’s hard to find MOSFETS much higher than this, but I’ve found some 250 or 300 volt units in the 100 Amp power levels.

Normally I wouldn’t worry about increasing the voltage range above stock too much (as my Nissan leaf battery pack is at 134 volts maximum), except that I believe I have found a good replacement for the diodes that are 600 v rated, and I may be able to upgrade the capacitors to 250 volt rating. So having a MOSFET rated to 250 volts minimum would be preferable.

One I found is:

IXTH110N25T

MOSFET N-CH 250V 110A TO-247

250v, 110a, 24 mOhm RdsON

Qg max = 157nC

The Diodes:

The stock diodes in my Curtis are marked “TSR2402R”, and others have said that Curtis used “MR2406FR” (24 amp, 600 volt, 1.15 Vf max, 250ns) or “SR4180R” freewheel Schottky diodes. (I’ve seen one reverse engineered schematic Marked 24 Amp, 200V, 300ns). They are in a TO-220 style case (it’s actually a button tab-mount diode, which is a button diode mounted between two metal plates or tabs that form the legs, but the same size as a TO-220 case. The rear metal plate is screwed to the heatsink. Finding replacement drop in diodes for the Curtis controllers is what most people say is the hardest part of a rebuild.

The key aspect of these diodes is that they need to be “reverse polarity”, with the anode connected to the tab (rear metal plate), so that they can be bolted to the M- rail/heatsink without blowing up. A drop in replacement is the “MUR2020R”, but their current rating and max voltage is low ( 20Amp, 200V, 0.97Vf, 95ns).

[As a side node, there are 18 of these diodes in parallel, so 24 * 18 = 432 amps, which feels low for a 500 amp rated controller, even if their peak repetitive current rating may be twice that.]

(David Mosher uses APT100S20BG diodes (200v, 100A, 0.89 Vf, 40ns), which are not reverse polarity, and insulates them from the heatsink with a silicon pad and connects them with wire extensions).

One option I found is the DIOTEC 7500 line. I’m specifically looking at the DIOTEC 7506R, because it is a 600V rated component available in reverse polarity in the TO-220AB form factor. (75A, 600V, 1.35 Vf, 150ns).

In addition to the generous 75A average forward current rating, the peak forward surge current is a whopping 800 amps! The only downside is that the forward voltage, at 1.35 average, is slightly higher than the 0.97v from the MUR2020 or 0.89Vf of the APT100S20BG’s, but it is close to the original 1.15vf of the MR2406R units. This means that the diodes will produce slightly more heat than stock. (But, if the MOSFETS are producing 1/2 to 1/5 of the heat, the total heat will be lower overall.)

As far as I can tell, none of my current diodes are broken. (Some of them have pieces of metal burnt off of their metal tab mounting case from arcing that occurred when the MOSFETS blew up, but my meter reads fine on all of them, so I think this is mostly cosmetic damage.) However, if I can replace them with 600 volt units that have a much higher amp rating than stock, it seems like I should go ahead and do it while I’m replacing everything else.

Aluminum Electrolytic Capacitors –

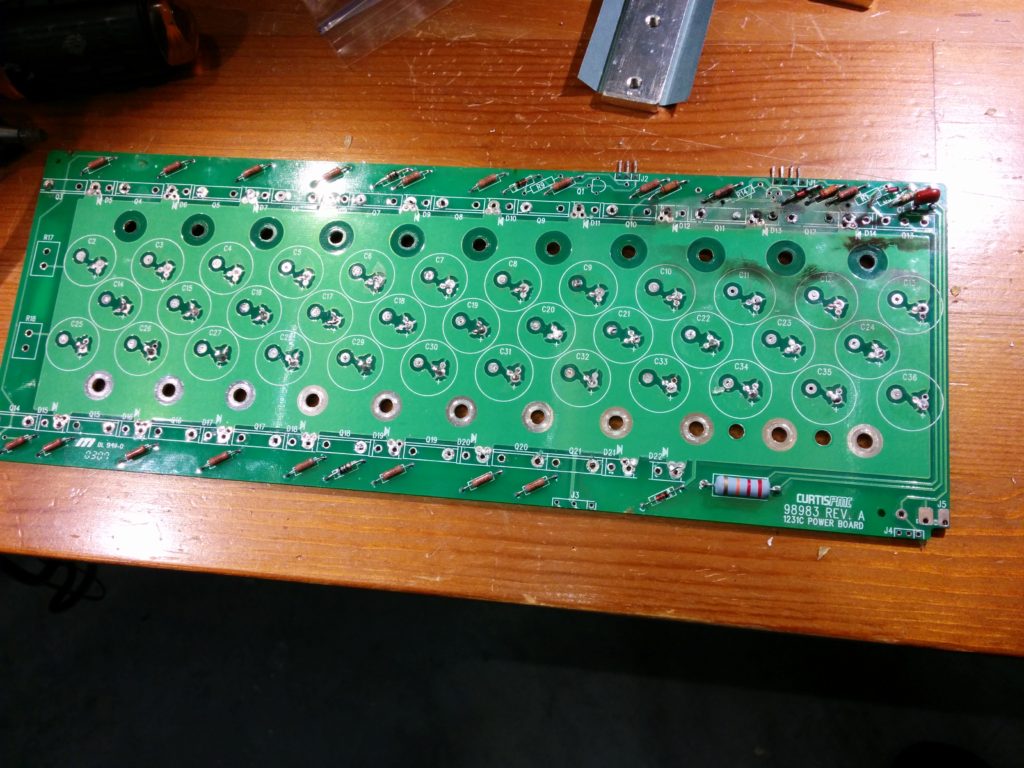

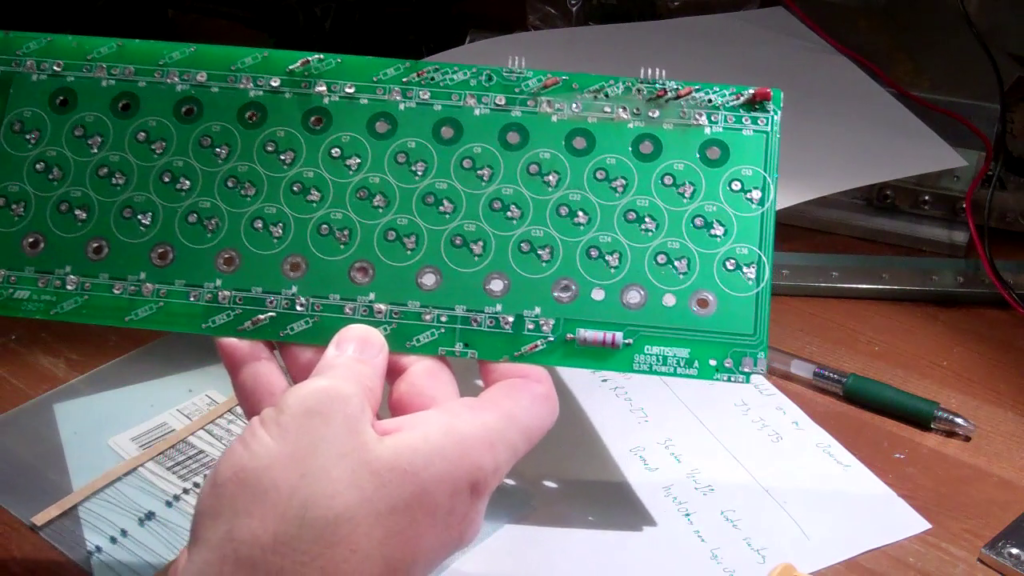

I believe that the aluminum electrolytic capacitors in my Curtis (for ripple control) are also working fine and undamaged. There are 35 of them on my power board, and they are 200 volt, 220 uF (micro farad) PS(M) Nichicon capacitors marked 105 ° C and H0735. They are approximately 1.6 inches (41mm) tall and 0.71 inches (18mm) in diameter, with what looks to be a 7.5mm lead spacing. [ I found an 18x40mm 220uF/200v in the PS(M) datasheet, code 2D 515. The 7.5 mm lead spacing matches up with the 18mm diameter.]

They are rated to meet specs after 3,000 hours of operation (with 22K miles, I estimate I’ve put 750 hours on them). They are also rated to perform to specs after being stored for at 105 ° C for “1000” hours (41 days), but I don’t know how that corresponds to calendar life when stored at ambient temperatures for 10 years. They had a DF (tangent loss angle), a measure of ESR of 0.15.

Electrolytic capacitors can fail due to calendar age, and if I’m upgrading everything else to higher voltage rated components, I may as well investigate upgrading the capacitors. However, higher ratings with capacitors almost always equate to larger case sizes, and I can’t fit anything larger inside the existing Curtis case. Finding capacitors with a 220uf or greater rating with a voltage higher than 250 in this form factor may be difficult due to the laws of physics, unless I decide to change from electrolytic to a more exotic (and expensive) composition.

My top choice for replacing them would be

Panasonic EEU-ED2E221 (P13533-ND) $3.94

220uF, 250V, 10,000 hours

It has the same capacity, the same DF (0.15), but a 250 volt rating, and 10,000 hours rated life.

Alternatively, I could go with an upgrade on the capacitance to 330 uF, but retaining the existing 200 volt maximum with:

Panasonic EEU-ED2D331 (P13524-ND) $3.94

330 uF, 200V, 10,000 hours

I’ve been told that upgrading the capacitance won’t buy me much from a performance or lifetime standpoint, so I’m leaning towards upgrading the maximum voltage to the 250V version.

The inexpensive option is basically the modern replacement part from Nichicon, with an upgraded 8,000 hour service life rating:

Nichicon UPW2D221MHD (493-2013-ND) $2.14

220 Uf, 200V, 8,000 hours

The difference in cost ($2.14 * 35 = $75 and $3.94 * 35 = $138) is about $63, if I were to buy them from Digikey (just about the most expensive place to buy electrical components…)

Pingback: Curtis 1231c Power Board desoldering | Jay's Technical Talk

Hi i am working on a Curtis 1204-015 DC motor controller and need to know if there is a replacement for the IR9049

Hi

I haw a defect Curtis 1225

and haw to replace 12 pcs NE22 Mosfets

Do you know a replasement / upgrade for them.

Best Regards

Klaus Bak

Denmark

I planned on using the IXTH110N25T Mosfets, which I purchased from DigiKey in the USA. (A move got in the way of completing this project, so I can’t confirm if or how well they work…)

I am looking fir a wiring scematic for my 1268 5403 curtis controller.

I have it a part ,there is NO 16volt to my 4 pin plug fir the programmer.

Thank you

Eric