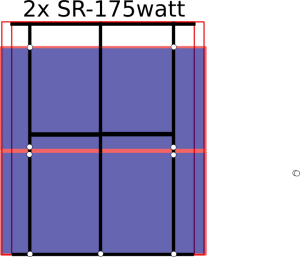

I purchased two used GE Energy GEPVc-175 watt solar panels and mounted them to the bedcover of my truck using 10-24 machine screws and T cone washers as rubber vibration dampers. Each panel weighs 31 pounds, and is rated to deliver up to 175 watts of power in full sun (at around 36 volts each, or 73.4 volts at 4.7 Amps in series). I am still waiting on a group of Georgia Tech ECE students for the magic box that does maximum power point tracking (MPPT) and voltage boosting to charge my 120 volt battery pack, but I hope to be generating 1-3 miles of my daily commute from the sun soon. As my daily commute is 4 miles, this can be a significant percentage of my total energy usage.

I have calculated that in the summer the panels are far enough behind the cab that they will not be shadowed by it, even if I have to park facing south. In the winter and early spring / late autumn I need to park facing north to avoid shading a strip of the solar panels.

I still need to figure out a way to tilt the panels towards the sun to collect as much energy as possible. This is especially critical during winter, when the solar angle is way off of vertical. As the bed cover tilts, AND the bed of the truck can tilt (the other way) I figure I can work something out (with a few pieces of wood cut to the correct height, or linear actuators if I want to get fancy.

Pingback: Adventures with a boost converter — Jay’s Technical Talk

I would like to implement a MPPT on a PIC controlled system: any help for the program ?

I have to charge a 12 v sla battery using a PV .

Thanks

Bye

Ambrogio

I am still working on the code for a MPPT as part of a boost converter. You can see my initial schematic here:

https://www.summet.com/blog/2012/01/22/boost-converter-schematic/

Note that my system is more complicated than what you want, as I am boosting the voltage up. For a 12V battery charger, you could get away with a simple MOSFET switch acting as a PWM, so that you could choose what voltage to keep the solar panel at. The other parts of my schematic (current sensing, voltage sensing) will be useful for you, but you could replace the inductor/capacitor boost part with just a single PWM ing MOSFET and a filter capacitor.

This seems like a good idea in theory, but how do you haul anything in your truck if it is loaded with a solar panel? Seems impractical.

95% of my trips in the truck are for commuting to the train station, not hauling stuff. For trips to the grocery store I can simply slide bags in via the tailgate. For large items, the panels are mounted to a hinged bed cover. I can tilt the cover up about 45 degrees which allows me to put relatively large items in the back of the truck without removing them (if I’m willing to rest the cover on top of whatever I am carrying). Worst case scenario, with another person to help me lift, the entire cover can be taken off the back of the truck, panels and all.

hi jay,i have built my own solar panels and want to start a truck,your s-10 is my exact vision!i would also like to figure out how to charge on the fly…i have an old guy that has a patent on a horizontal turbine and was thinking of mounting these on the bed the same as your panels..i also have found batteries that 1 would replace 4 reg deep cycles (120lbs each)also do you need higher voltage or amperage for max efficientcy?i was hoping to go 100 miles on these 4 batteries? oh how much do have in your build? any direction on how to go would be appreciated thanks

Hi Phillip,

I have 20 six-volt golf cart batteries in my truck (they weigh about 1200 lbs total). It sounds like you have about the equivalent to 16 of my batteries (or perhaps 8….my batteries come in close to 60 lbs each). So, it sounds like your batteries would have less capacity than mine. With my battery pack I can easily drive 20 miles. If I push the battery pack, I can drive 30 to 35 (and completely destroy the batteries by discharging them to 0%). My truck does not have low rolling resistance tires on it, so if you had less weight and super low rolling resistance tires, you could possibly get a similar range with your S-10 and the batteries you described.

However, to get a 100 mile range you must go with Lithium Ion batteries, and they will cost many thousands of dollars. I find that 20 miles a charge (I can drive 40 miles in a day if I charge in the middle of the day) is plenty of range for my short commutes. If you are regularly driving 100 miles a day, a fuel efficient hybrid car may be a better choice for you.

The solar panels provide very little energy (Enough for almost 2 miles of driving a day), and I suspect a wind turbine that low to the ground wouldn’t provide much more power unless you live in a very windy area, so plan on plugging in your truck. You might want to check out this website for S-10 conversion information:

http://www.evamerica.com/evtrucks.html

great work. We are working on a solar powered truck with a tipper.. see our blogs .. http://www.sunstore.co.uk/Electric-Van/

we have it working now and are just about to implement the 640w of solar panels and a tracker system to get the best harvest. Here in the UK the winter sun angle is so poor, 16 degrees at its worst!

I put a down payment reserve on Rivian’s 2020 pick-up truck. I also sent them an email suggesting they do exactly what you’ve done here. Install a solar panel in the flat bed floor. I haven’t heard back from them yet though.

has anybody thought about the new f150 lighting and putting solar panels on it to charge the batteries to get more rande out of it?

I know Tesla has with the Cybertruck. https://electrek.co/2021/05/27/tesla-cybertruck-retractable-solar-bed-cover-revealed-patent/

Dear Sir or

I am writing to request technical and commercial information regarding a turnkey electric conversion kit for a 1979 Chevrolet C10 (Squarebody).

In addition to a complete EV conversion, I am specifically interested in a solution that can integrate a solar panel system installed over the entire truck bed in order to recharge or assist in charging the battery pack (auxiliary or main charging support).

I am looking for a ready-to-install solution that ideally includes:

Electric motor and controller

Adapter/interface for the existing transmission (manual or automatic)

Vehicle Control Unit (VCU), if required

DC/DC 12V converter

Onboard charger

High-voltage safety components and wiring

Technical installation documentation

Concerning the solar system, please specify:

Compatibility with solar panels mounted on the full bed area

Recommended solar panel type and total wattage

Charge controller / MPPT integration

Whether the solar system charges the main traction battery or an auxiliary battery

Expected charging contribution (range per day, kWh/day estimate)

Please also provide:

Confirmed compatibility with a 1979 Chevrolet C10

Motor power and torque specifications (kW / Nm)

Recommended battery configuration (chemistry, voltage, capacity – included or not)

Pricing for:

EV conversion kit

Solar charging kit (if separate)

Current availability / stock status

Lead time

Shipping options and costs to Tahiti, French Polynesia

Real photos of the kit and, if possible, completed conversions on pickup trucks or similar vehicles

This project is part of a serious electric conversion of a classic pickup truck, with a strong focus on reliability, ease of installation, energy autonomy, and cost efficiency.

Thank you in advance for your time and I look forward to your reply.

Kind regards,

Moana

I’m afraid I do not have a suggestion for you. Good luck!