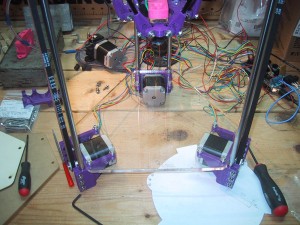

I have the endstops, automated homing, and steps per mm set up correctly so that my rostock mini can run gcode and “print” an object. Of course, I still need a printbed, and an extruder cold / hot end before actual printing will happen. Also, I’m still using my 1/8″ plywood prototype frame pieces, so it wobbles around a lot with the vibrations. Once I finalize all of the mounting holes, etc, I’ll be switching out to a full 1/4″ acrylic sheet on the top and bottom.