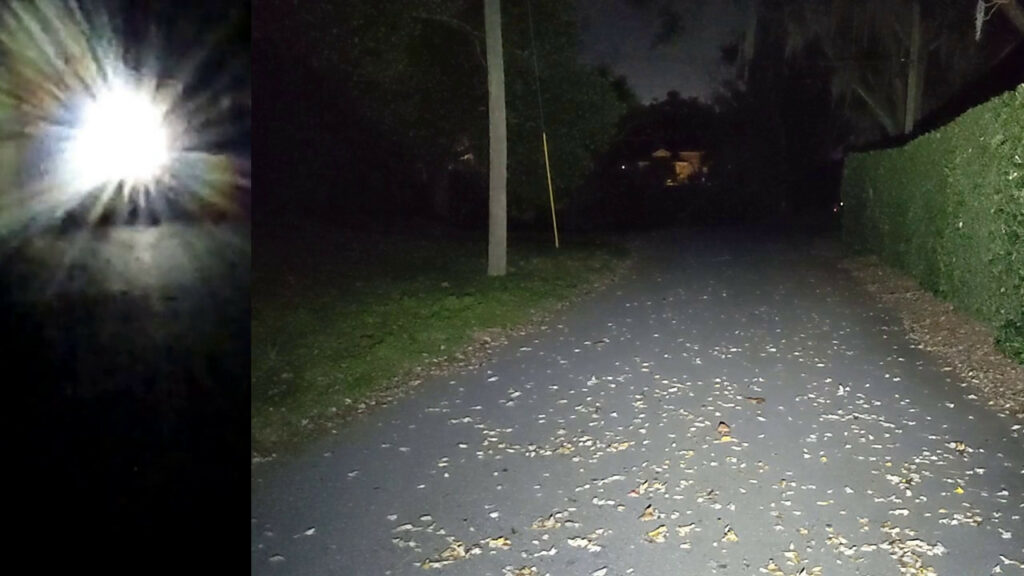

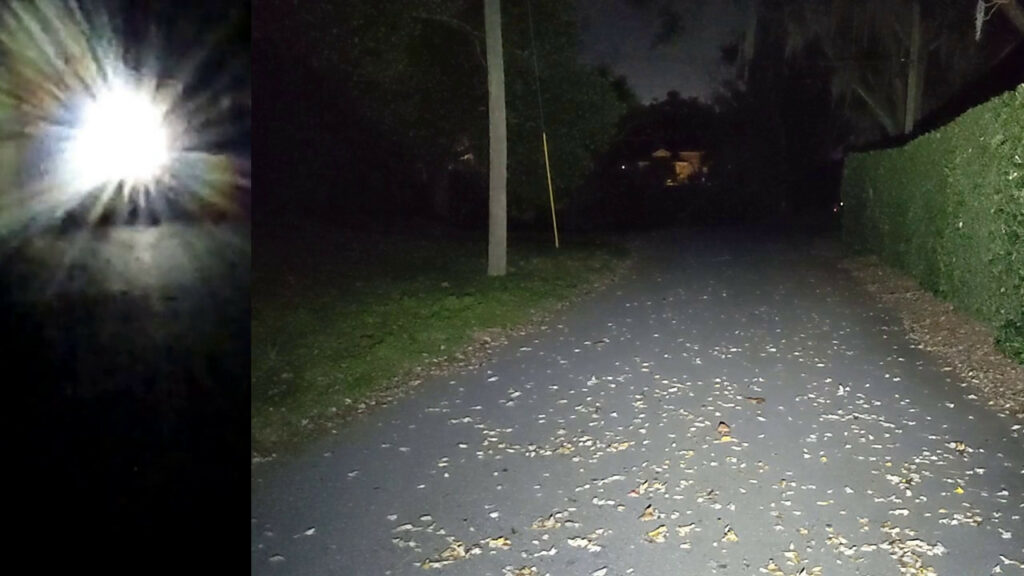

The Ravemen PR1400 bike light ($70 as reviewed) is VERY bright in the HI / EMERGENCY mountain biking mode. Plenty of light. Blinding light. More than you should have on a road bike.

HIGH / Mountain Biking / EMERGENCY full power mode with both “high” and “low” beams at full power

Although it claims a 1.5 hour runtime in the highest setting, it actually goes for 1 hour 45 minutes in my testing, because it was producing so much heat the light would thermally throttle the light output and occasionally drop down to the “medium” setting until the light cooled down. [I was testing statically on a garage floor, so it may get more cooling airflow if you are actually riding it on a bike…]

High light setting in road biking (low beam) mode

The “road biking” modes deliver a more reasonable amount of light and it is aimed lower (think, low beam vs high beam). You get a High/Medium/Low/Eco mode in the road bike mode.

The eco mode claims to deliver 22 hours of battery life (I didn’t test this, but I believe it, as it is much dimmer than the high powered modes). I think this mode provides enough light to walk, or bike along at a walking pace, but I’d want to use the “low” mode at a minimum for most biking at night. There is also a “pulse” mode which appears to cycle between the medium and eco modes, and makes you more noticeable to drivers. Continue reading →