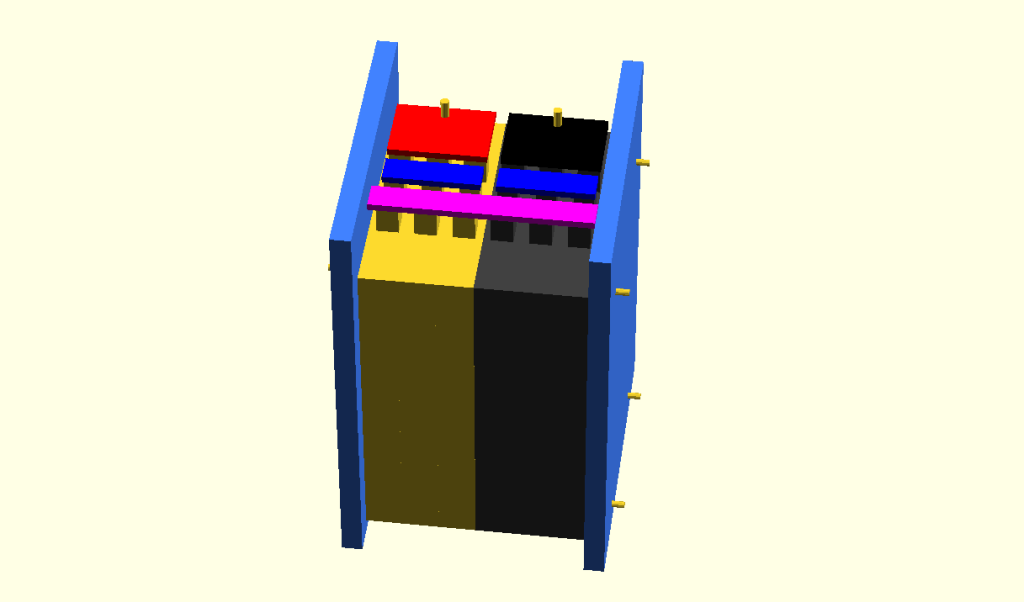

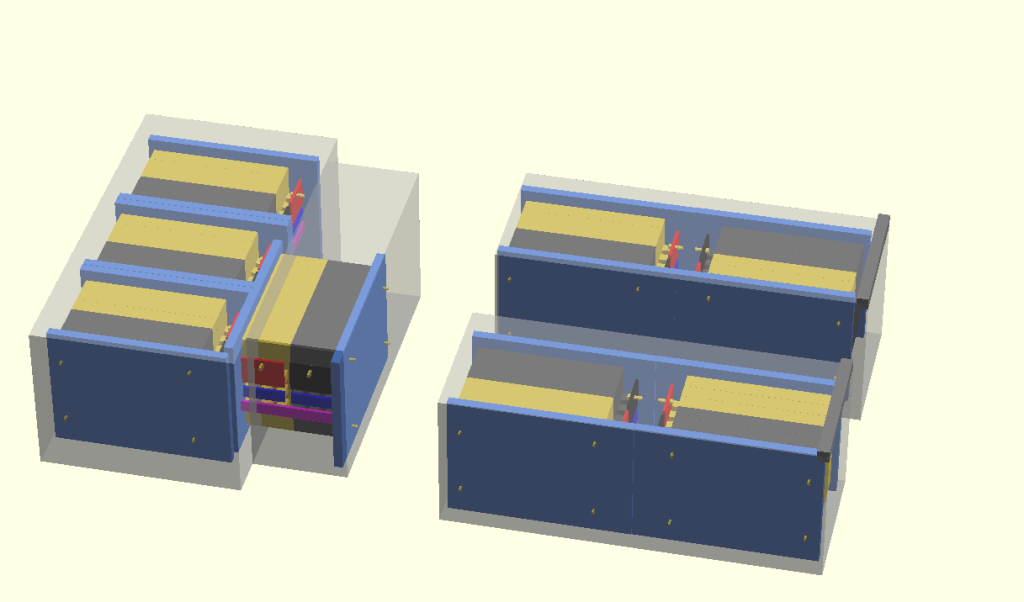

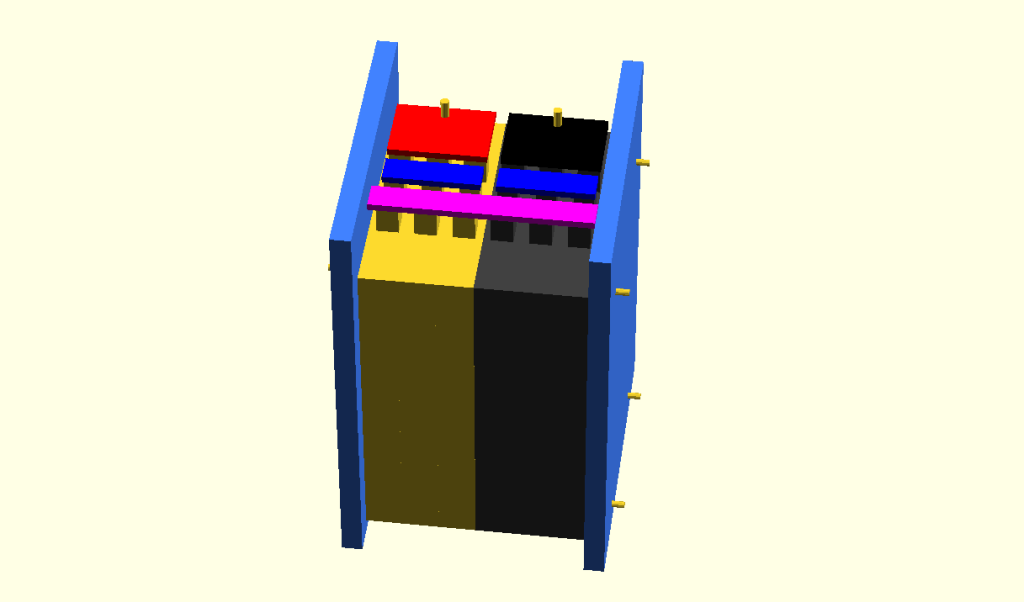

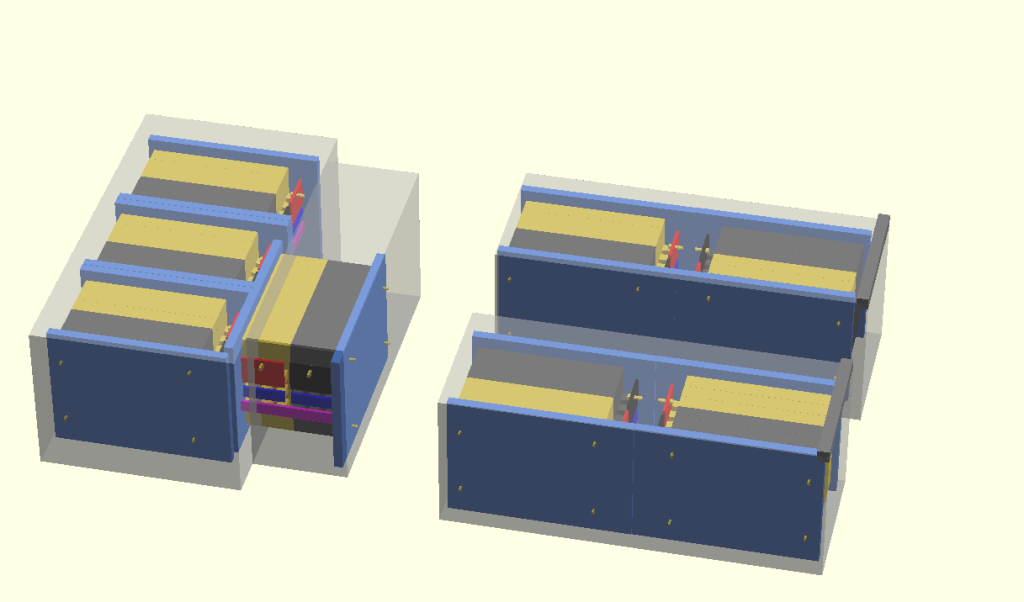

This is my current CAD mockup of how I will package a group of six Nissan Leaf modules. I have 48 total modules from a Leaf battery, so I will have eight of them to distribute throughout my truck’s battery bays. I also have a CAD model of that:

Unfortunately, my existing Lead Acid (golf cart battery) bays are not tall enough to mount them vertically, so I am having to lay them sideways. This results in terminals being relatively close together in the two side bays. (I’ll probably slide a sheet of plastic between the two batteries after I get them installed to make it more difficult to drop a wrench down there and short things out. It’s only 32 volts total potential, but a lot of Amps!)

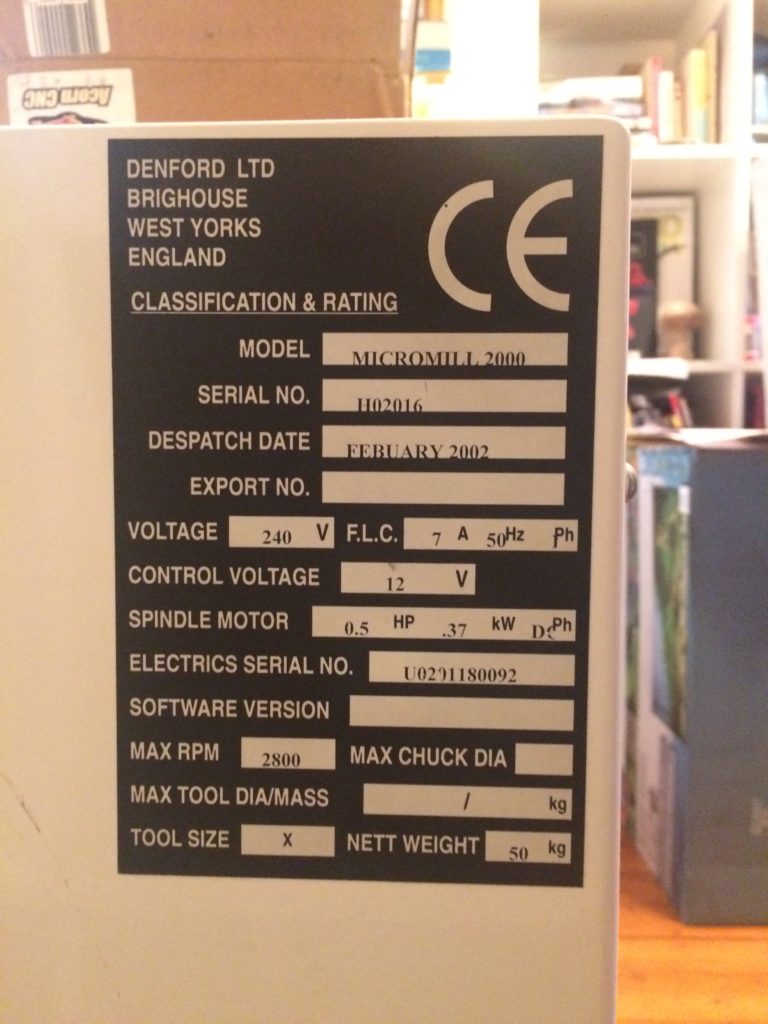

If you would like to know the specifications of a single module (and some people have asked) here is what I know:

From: http://www.electricvehiclewiki.com/?title=Battery_specs

Confirmed by Jay with a 2013 Nissan Leaf module.

lm_width=223; // mm – 8.7795 inches (measured 222 – 8.75 inches)

lm_length = 303; // mm – 11.9291 inches (measured 298.45 or 11.75 inches)

lm_thickness = 34; // mm – 1.3779 inches (measured 34- 1.3333 when compressed)

lm_weight = 3.8; // kGrams, or 8.3775 lbs

The power “bolt blocks” are 20×20 mm in size, and I modeled them around 1 inch in height. But, this height includes the space for a bolt head and a busbar on the top. In the CAD model I made them one inch tall, but in real life they are slightly shorter than that. The “bolt blocks” for the sense terminals in the middle are slightly smaller (18×18 mm) but the same height. So if you download my CAD model (link below) keep in mind that the top of the bolt blocks on the module includes a little extra wiggle room. The CAD software I use is OpenSCAD, which you can download for free. The file itself is human readable text.

BatteryPacks.scad (You may have to rename it from BatteryPacks.scad.txt to BatteryPacks.scad )