I purchased a 2013 salvage (wrecked) Nissan Leaf from the CoPart auto auction house for $4081 (including delivery and fees). I consider this to be a very good price for a wrecked Leaf, but if you stalk a lot of auctions and bid on Leafs that have the most damage you can probably get a similar deal with enough patience.

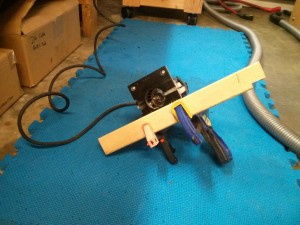

Then I spent 439$ on the following tools that I needed to move the car around and extract the battery (the largest amount was for jacks and wheel dollies…)

| Car Cover (Keep the neighbors happy) |

37.1 |

| Wheel dollies & Jacks |

243 |

| Bluetooth OBD II scanner |

9.98 |

| Leaf Spy Pro android app (to check battery) |

14.99 |

| 500V gloves (Safety first!) |

21 |

| 2 Jackstands (already had 2) |

25 |

| Air Impact Wrench & Sockets |

46.5 |

| 18mm wrench |

12.4 |

| 13mm deep socket |

8.99 |

| 21 mm combination wrench |

20.69 |

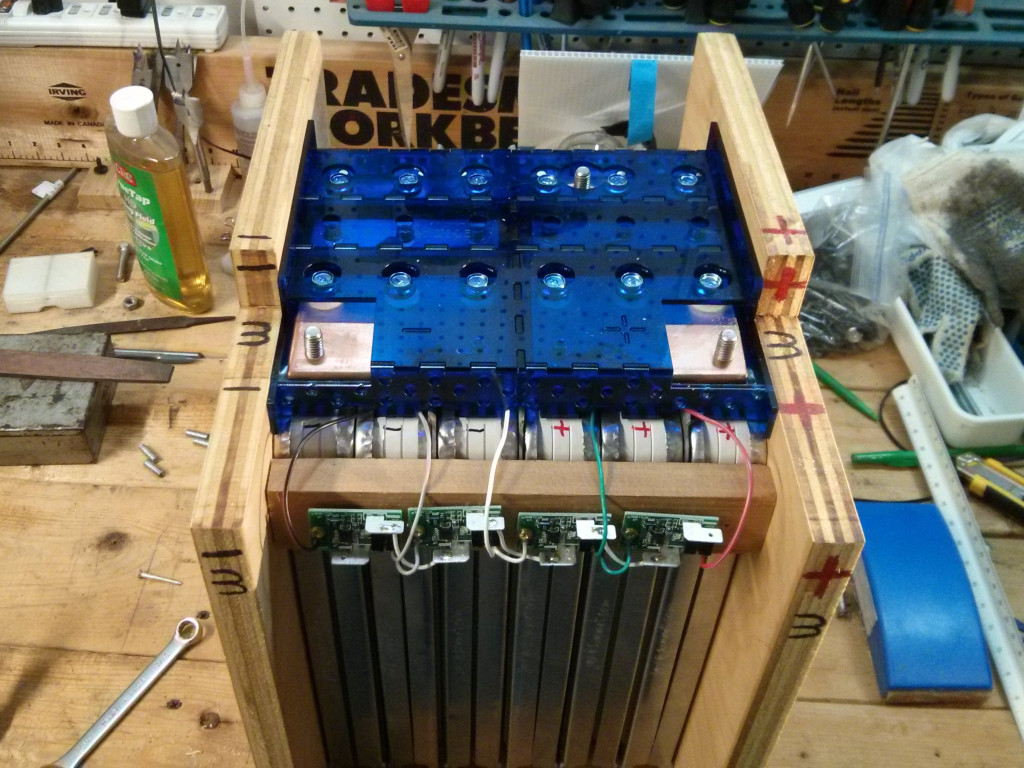

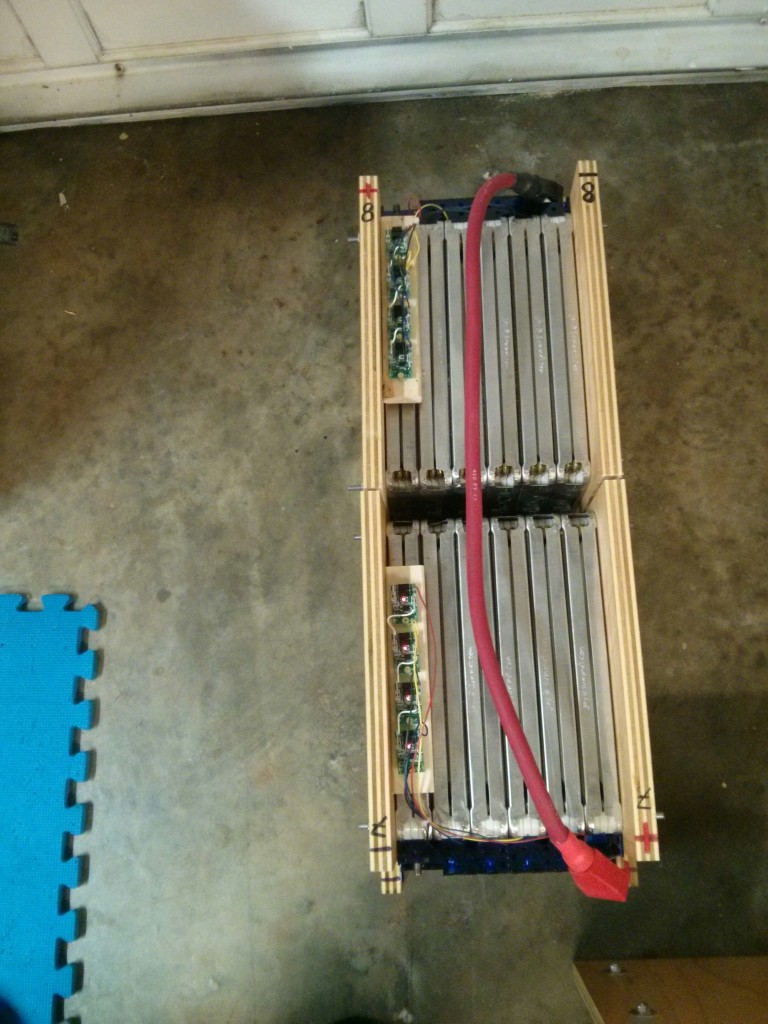

This puts my total costs at 4520.75 ($94.18 per module) for a 24 kWh battery pack, which is less expensive than if I bought large format prismatic cells.

Of course, with a lot of time and effort, you can sell all of the other parts from the car. Over the course of six months I made back $3180.46 (including the sale of the smallest of the three jacks I had purchased and 0.46 in change I found in the car.) I’m posting this after selling the main body of the car, leaving me with just a few small items listed on ebay. I may earn a few hundred extra dollars over the course of the next several months, but the overall cost recovery is finished.

My current total out of pocket expenses (not including lots of labor!) is 1340.29 (or $27.92 per module) which is quite a significant savings over other options for purchasing large format Lithium Ion batteries.

I’ve seen Nissan Leaf modules selling on Ebay for around $130 each with shipping (in larger quantities), so my ~ $30 per module cost is around 21% of the cost of purchasing them on the used market.

To put this cost savings in perspective, purchasing 20 lead acid golf cart batteries to replace my current pack would probably cost me around $2000-$2200, so the Lithium Ion Nissan leaf battery pack was actually less expensive than a replacement lead acid pack!

However, the process of parting out the wrecked car takes a lot of time and effort. If you are just after the battery and can find one for sale at a salvage/junk yard for less than $2500 it would probably be easier to buy the battery alone without the rest of the car. The one advantage of purchasing the whole car is that you can (sometimes) find out how many miles are on the battery pack. In my case, I was able to use an OBDII scanner with the Leaf Spy Pro application to find out that my battery pack health was still at 98% before I removed it from the car.

If I were to buy a whole car again, I would try much harder to sell the entire car (minus battery) in the $2000-2500 range before parting it out and trade some money for my time.

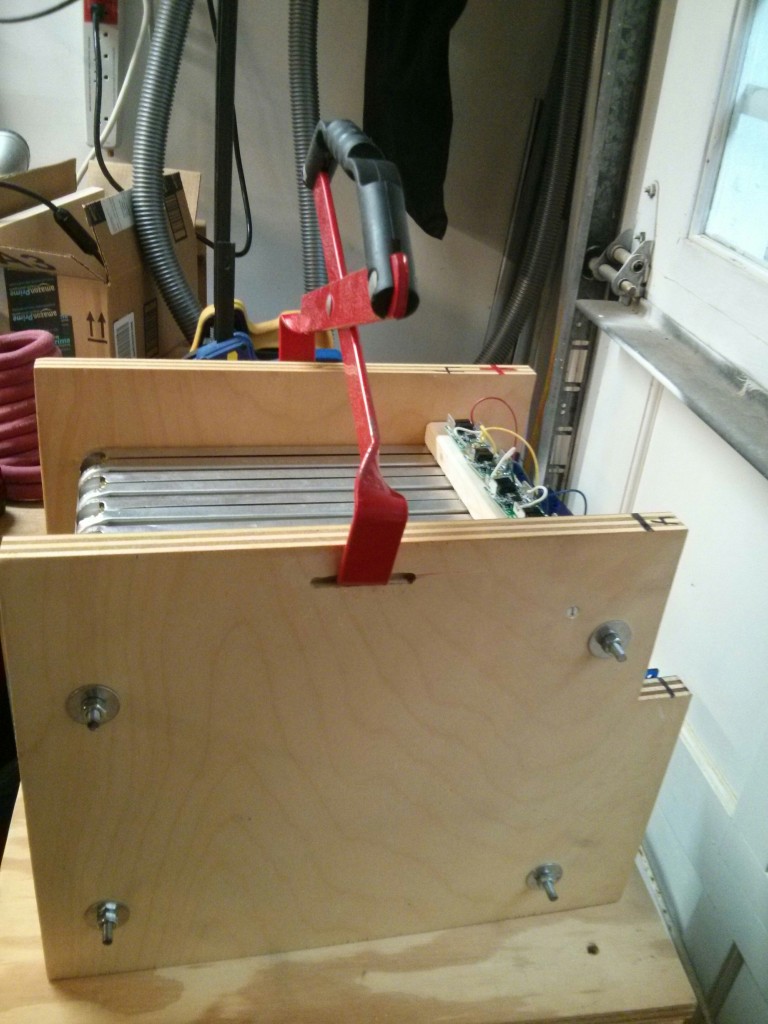

The Nissan Leaf pack weighs about 650 lbs less than the lead acid batteries currently in my truck. They are capable of providing more amps with less voltage sag due to lower internal resistance, and more of the pack capacity is usable as they don’t suffer from the Peukert effect as much as lead acid batteries.

The overall performance of the truck should be much improved. Also the battery life should be much longer than 2 years. (Cycle life for lithium ion batteries is measured in thousands of charge cycles, instead of hundreds of charge cycles for lead acid batteries.)

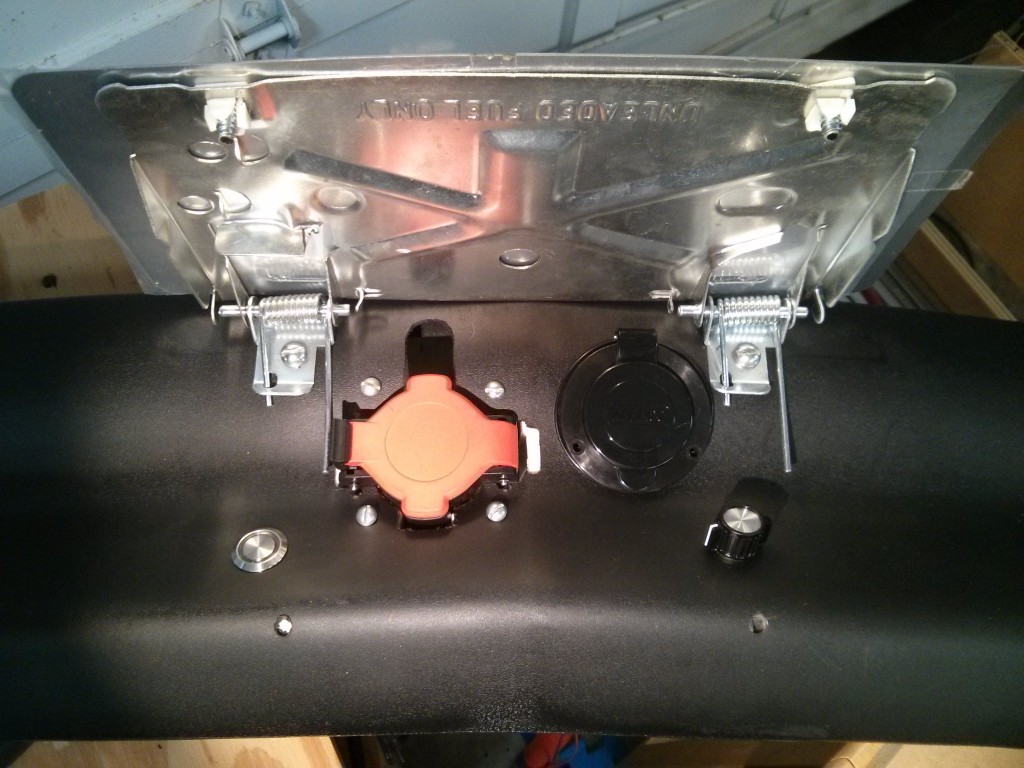

However, because I am changing battery chemistries, I am also upgrading my trucks’ charging system (and home EVSE) and those costs are actually more than the battery pack, so the total upgrade cost will be more than just getting another lead acid battery pack. (I will talk more about charger upgrade costs in a later post).