I purchased a 21″ Self Propelled EGO lawnmower in April of 2017, and although the mower’s manufacture date code was listed as Sep 2016, the 7.5 AH battery (Original Battery) that HD gave me (shipped separately and lost for a week) had a date code of Dec 2014.

I just (July 2018) purchased a second brand new 7.5 AH battery that has a manufactured date code of May 2018 so that I can mow twice as long, and be charging one battery while mowing with the other.

To monitor the performance and lifespan of these (relatively expensive) batteries, I have been periodically testing their capacity by draining them to the same level (when the red light on the mower comes on) and then measuring how many watt/hrs it takes to fully recharge them using a Kill-a-watt meter. In this way, I can compare the original battery (both last year and now) to my new battery.

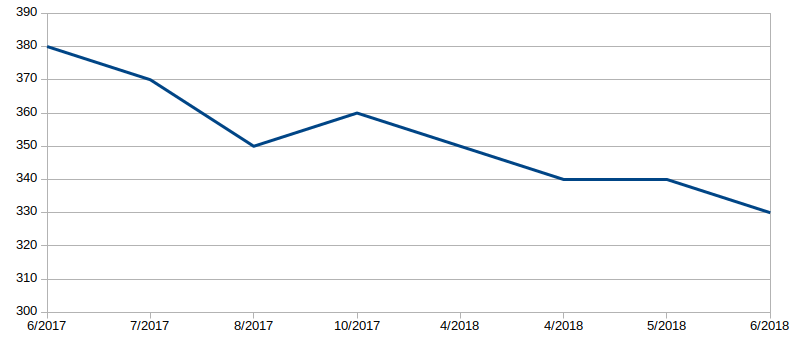

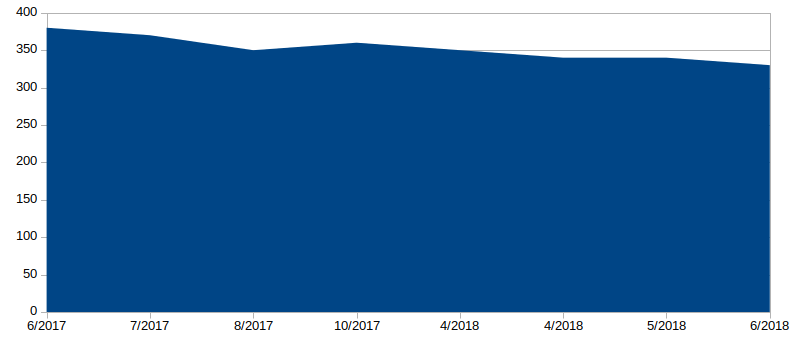

Here is my data:

Original Battery Aug 2017: 380 watt/hr to recharge

Original Battery July 2018: 330 watt/hr to recharge

New Battery, July 2018: 410 watt/hr to recharge.

I didn’t start keeping track of how much power it took to recharge the original battery until August of 2017, so I don’t know if it was at the 410 level when I originally received it or not. It’s calendar age from the date of manufacture was 2+ years old when I received it in April of 2017, and I estimate it probably lost 7% of its capacity before I started the measurements.

Conclusions:

The original battery has lost approximately 13% of it’s capacity over the last year from the point I started keeping track.

(380-330= 50 / 380 = 0.1315 )

Right now, my brand new battery is 19-20% “better” than my original battery (which is 3+ years old and has been in active use for 15 months).

(410 – 330 = 80 / 410 = 0.1951)

Said another way, my original battery still has 80% of the capacity of a “new” battery after 15 months of use and several years of storage before I purchased it. (330 / 410 = 0.8048 )

Just for fun, here are two graphs of the data points I have for my original battery over time. The first one shows how the degradation appears to be mostly linear (at least over the last year) but looks scary, because OpenOffice cheated and auto-scaled the vertical axis to only include the data points.

This second graph represents the total capacity “under the line” is a better visual representation of reality, as only 13% of the original capacity was lost over this time period (20% when compared to a brand new battery, so the other 7% was likely lost in the years of storage before I received the original battery).

Update: See my next post for two years of usage data on my original battery, and 1 year on the new battery.