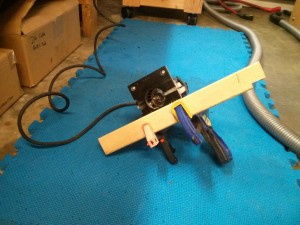

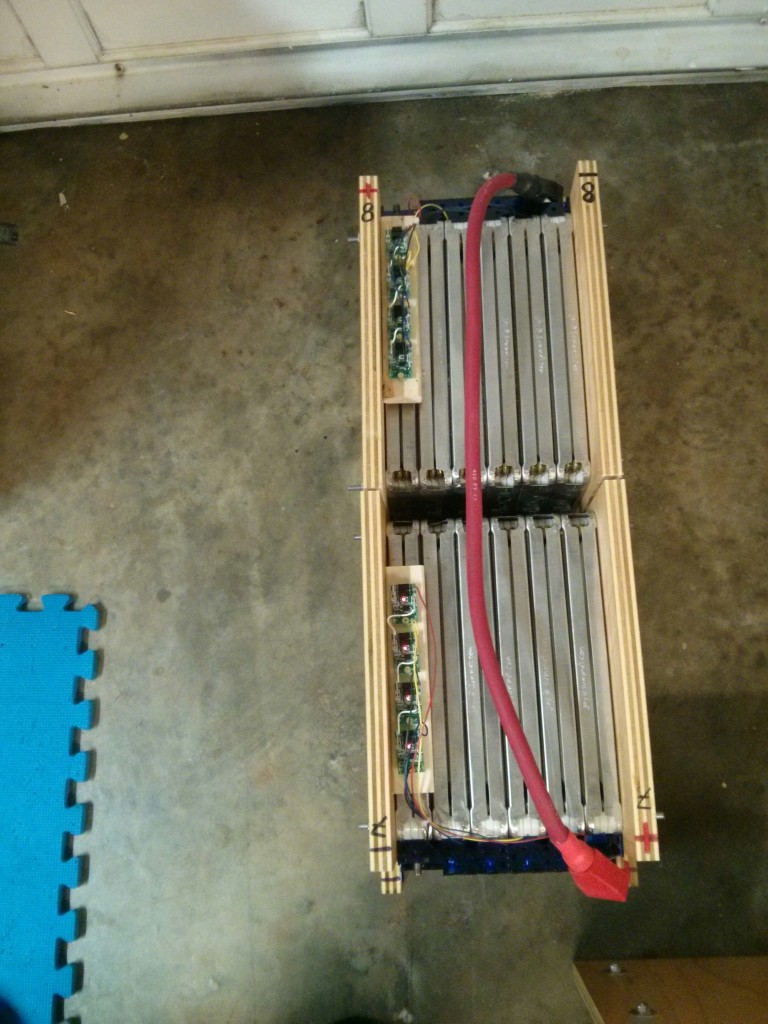

This is a Battery Carrier tool designed for picking up and carrying around lead acid batteries (golf cart or starter batteries). I own one because it’s very useful when removing 20 golf cart batteries from my S-10 electric pickup truck and replacing them with 20 new batteries. While manhandling my Nissan Leaf batteries around my garage, I though “Boy, it sure would be nice to be able to use my battery carrier on these guys.” A few minutes spent rigging up a jig for my trim router and vacuuming up a lot of saw dust later, each of my batteries has a small slot cut in both sides…

I had thought that I would have to sell my battery carrier and battery filler now that I am upgrading to Lithium Ion…I guess only the battery filler will be obsoleted.

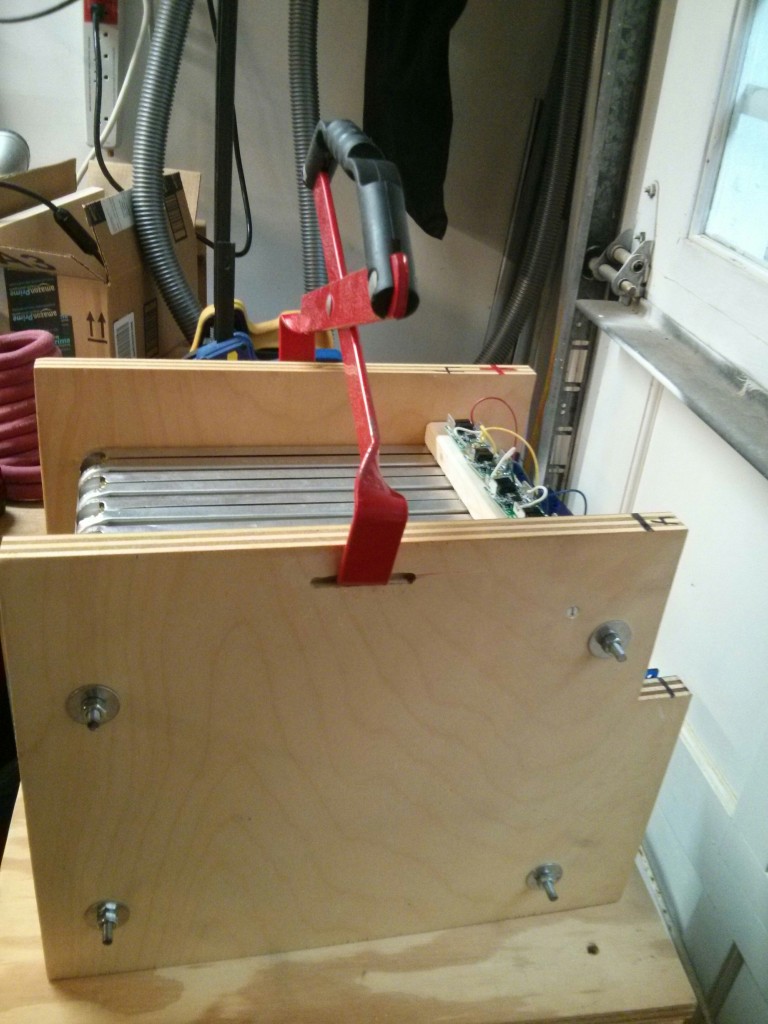

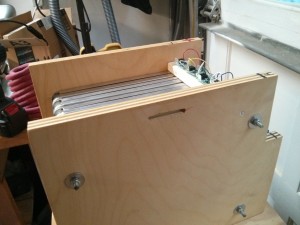

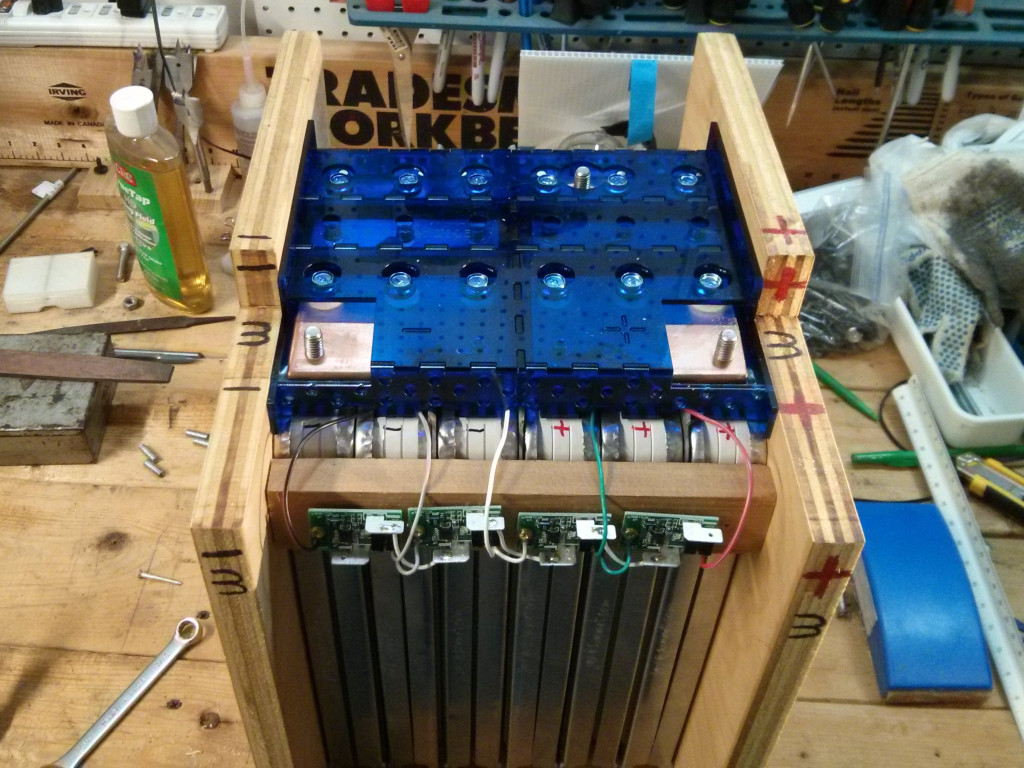

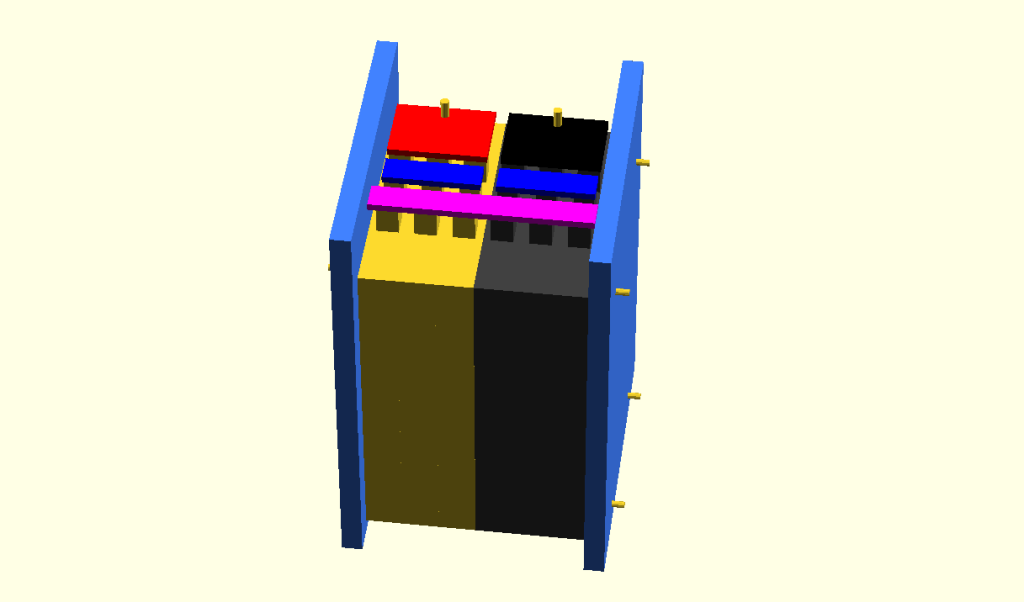

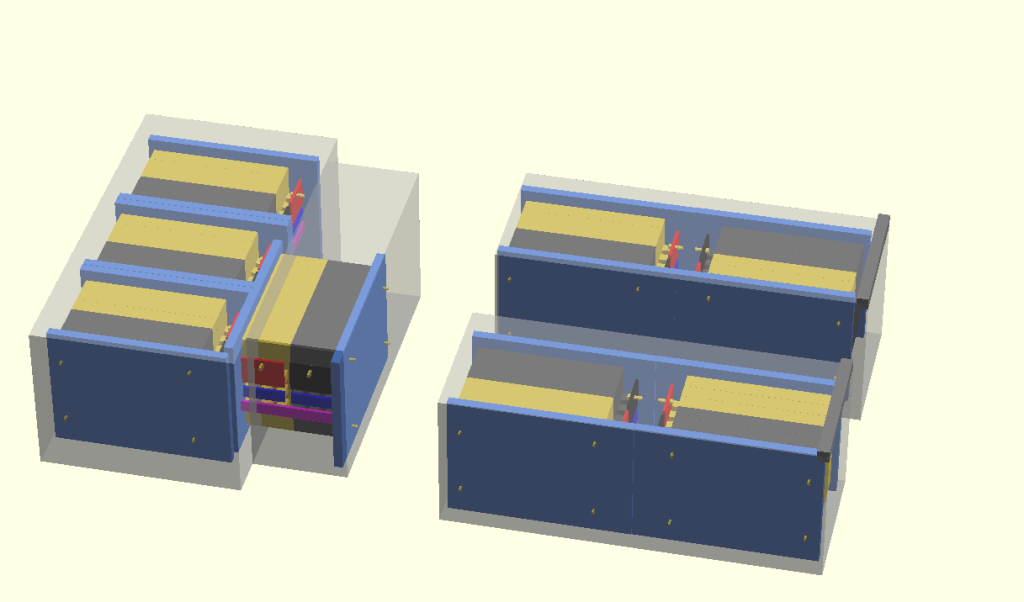

I also modified a few of the batteries to better fit in my existing battery bays. Specifically, I decided that batteries 1&2 and 7&8 would be mounted “back to back” and I didn’t need each of them to have a full 1″ of space at the bottom, so I cut a 1/2″ off the bottom of each, giving me an extra inch of room, and leaving them a shared 1″ air vent.

On battery 3, which will be mounted “sideways” with respect to batteries 4,5 & 6, I used a spade bit to sink the washer in a little, and cut off the ends of the threaded rod to make sure they wouldn’t interfere with cables.