If you are removing a stripped out screw, and have to apply pliers to the head to get it to turn, but after backing it out a few turns the head shears off, you can always use a rotary cutting tool to make an old school regular screwdriver notch in it.

Lathe Break Out Board mounting

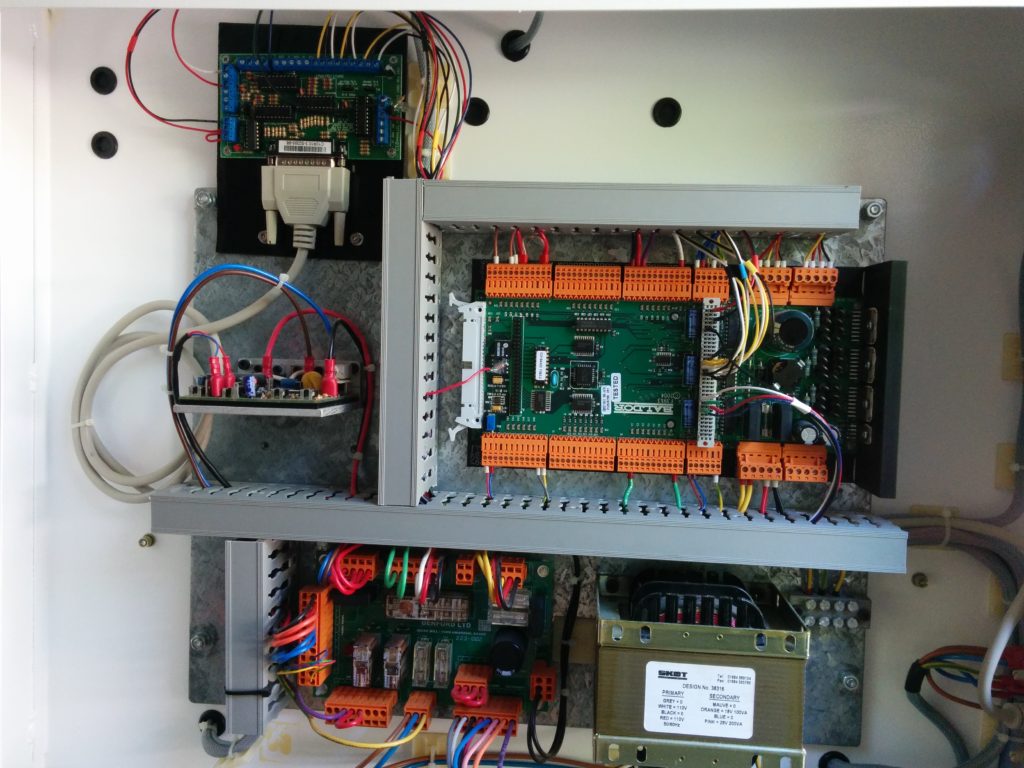

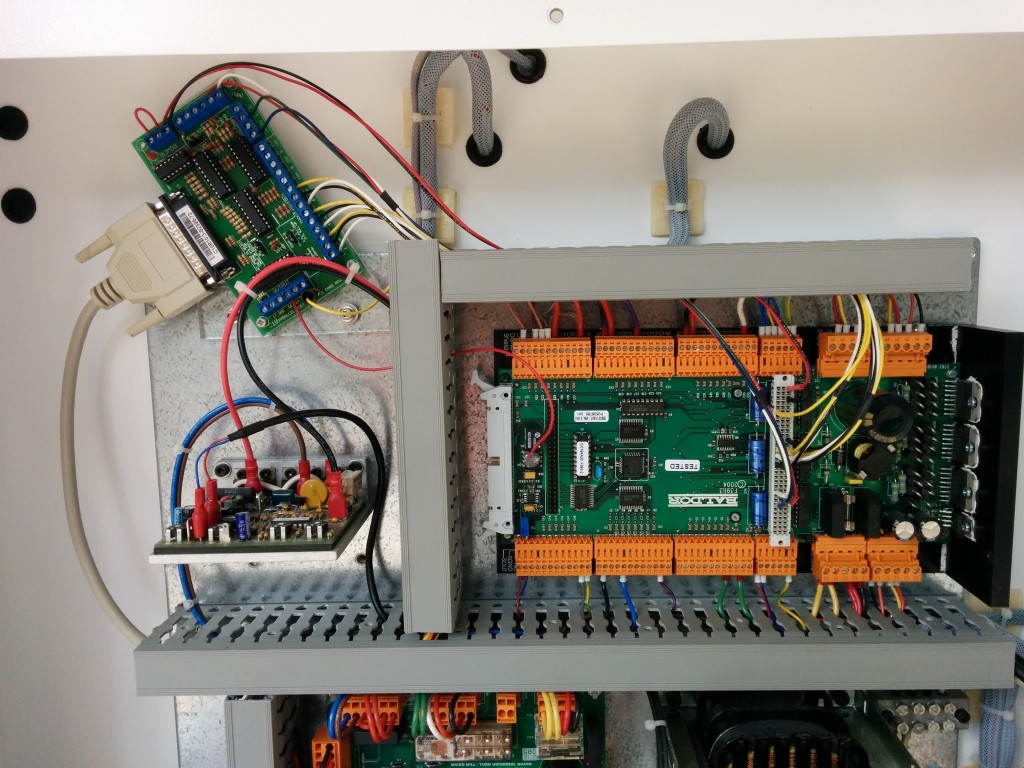

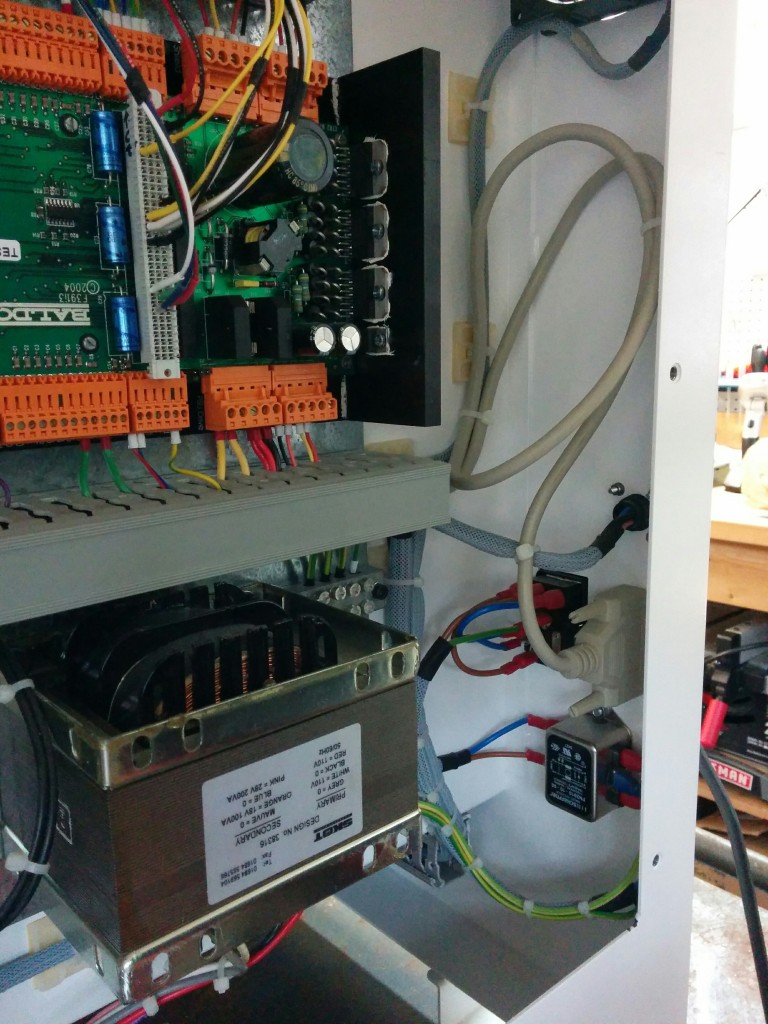

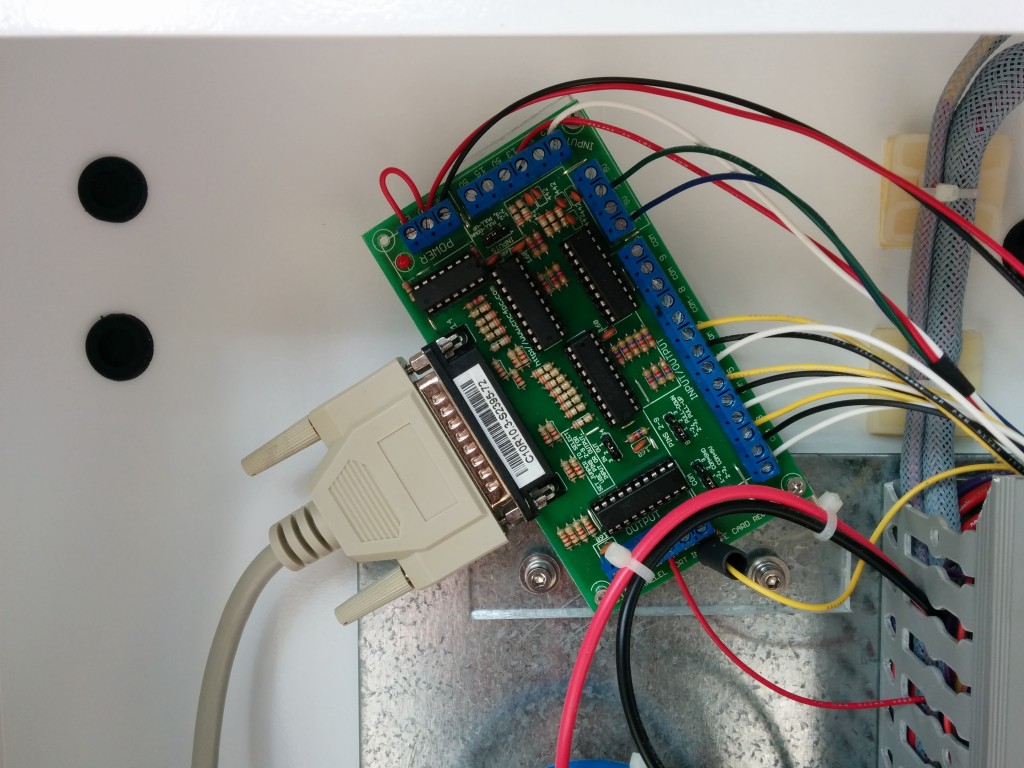

Here is a picture of the final wiring layout of my Lathe after installing the parallel port break out board (top left). I made use of the built in wiring trays to organize all of my wires that plug into the 96 way header on the NextMove ST stepper controller board.

Here is a closeup of the break out board and it’s acrylic mounting plate.

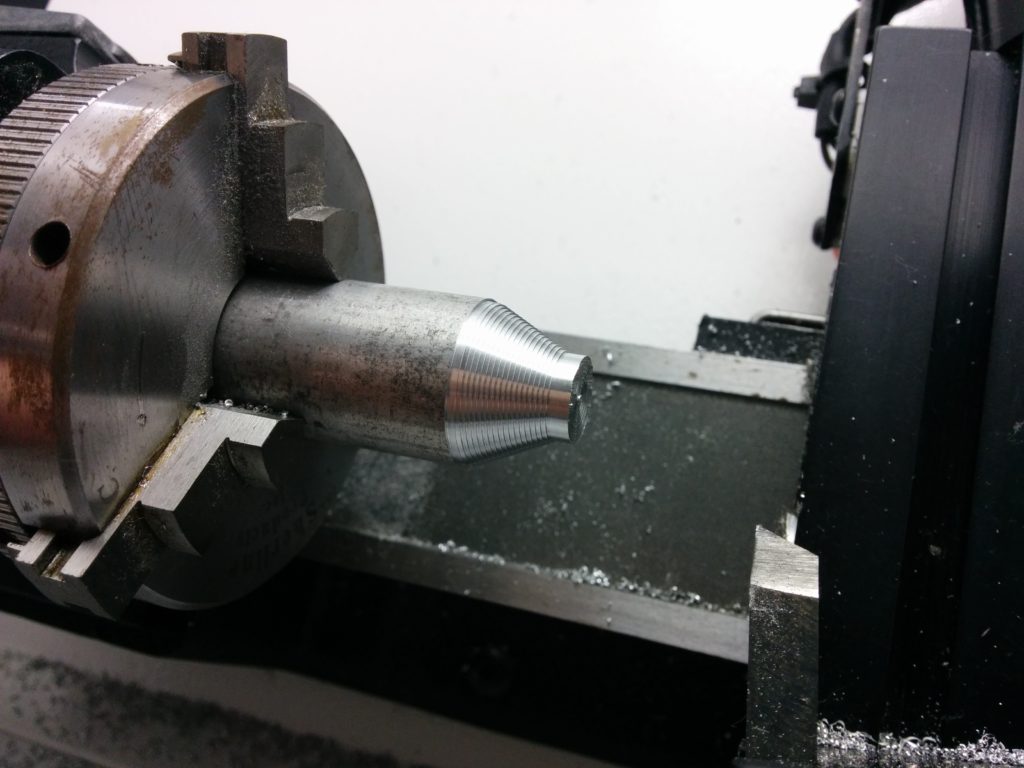

Scantek 2000 CNC Lathe – First cut with LinuxCNC

I converted my Scantek 2000 CNC lathe to work via Parallel port control (for Mach3/LinuxCNC software control) and have been learning how to hand write gcode (because the Linux compatible CAM lathe software options are not terribly good).

Unfortunately, the LinuxCNC software doesn’t support many of the automated cycles (G71 I’m looking at you!) for lathe turning (yet!), so I had to write up a gcode file with many manual G1 passes to cut down the cone shape you see here.

Instead of hand coding the whole thing, I wrote a small python script that automated the gcode generation, which takes 0.2 mm passes off the stock, stopping 0.5mm shorter each time from 10mm down to 5mm radius. But I did the first few by hand….

Here is a video of the process in action:

And below is the full gcode file for those who care….

Monster UPS just got bigger….

A few years ago I built a Monster UPS using an RV Inverter/Charger and two golf cart batteries. Seeing as how I have a lot of extra golf cart batteries just hanging around, I upgraded it to use eight GC2 batteries (that’s 720 AH x 12 volts, or 8.6 kWh when new). Because more is better, right? (Except for the 500 lb system weight…which is probably getting close to the capacity of the steel cart I’m using to make it semi-mobile.)

MicroMill Mach3 / LinuxCNC conversion complete

I have mounted the parallel port break out board inside the enclosure of my ScanTek 2000 (Denford Micromill). I routed the parallel port cable out to the previous DB25 (RS-232) outlet on the case and sealed up the back.

With the built in wire management trays, the job looks almost professional…except for the fact that I used a triangular piece of 1/4″ acrylic scrap I had for the mounting plate, so I had to orient the break out board at an angle. But since it’s inside the case, nobody can see it anyways.

Outside the case, the only visible difference is that I took off the black “RS-232” sticker that used to live next to the DB-25 connector. Continue reading

How far can it go?

Summary: I drove my truck 46 miles on one charge (and had some juice left over).

When you have an electric vehicle, everybody wants to know how far it can go.

I typically tell them “19,800 miles so far.”

But then you have to answer their real question, which is “What’s your range on a single charge?”. If you have a commercial EV like the Leaf or a Tesla, you can just refer to the EPA range figure for a nice apples to apples comparison. But when you have a conversion EV, the number is unique to your particular vehicle, motor, controller, battery pack and testing methodology. (And changes as the pack ages…)

I used to know the answer to that question for my truck with a (new) lead acid battery pack (“25-30 miles without killing the pack”), but I haven’t fully characterized the trucks’ power usage and range with the new (lighter weight, more powerful) pack made up of Nissan Leaf cell modules. My truck is heavier and has more air resistance than a stock Nissan leaf, the motor/controller is slightly less efficient, and the (big fat!) tires have quite a bit more rolling resistance. I figured “half the range of a Leaf” would be a good ballpark estimate.

Upgrading a 5 gallon portable compressed air tank

I was given this 5 gallon portable air tank, but you can purchase them from Harbor Freight or Northern Industrial in the $30-35 price range. It is filled with a car tire (Schrader) valve and has a built in pressure gauge, overpressure release valve and car tire fill hose.

I have a small garage compressor. It is a 1.3 HP compressor that provides 2.4 SCFM at 90 psi, which is reasonable if you need to blow stuff off, drive the occasional air wrench, or do some light spray painting, but not a very high output. It only has a 1.5 gallon tank, so if you start using a lot of air it doesn’t last long.

My plasma cutter wants 6 SCFM, which is more than the compressor can provide, but I only need about a 10% duty cycle. (make a cut, then move the metal, re-clamp it, set up a straightedge or jig for the next cut, etc…)

I bought some items in the tools / air-compressor isle at Home Depot to add the ability to attach the 5 gallon tank between my small compressor and the plasma cutter using standard quick connect fittings. The air fill hose that comes with the tank is mounted with a standard 1/4″ NPT connector, so all I need to buy was a T, a ball valve, a quick connection package, and a male to male adapter. I had to screw the pressure gauge 90 degrees to get room for both ends of the T.

One end of the T goes to the ball valve and the quick connect fill connector. This side is connected to the air compressor and allows the tank to be filled by my small compressor and to act as an air buffer. The other end of the T goes to the female quick connect adapter, allowing me to plug in any standard QC hose. I included the ball valve so that I could close it and disconnect the tank from the compressor and have it remain full, although primarily I’ll be using the tank “in-line”. The cost of these parts was $15, or about half the cost of the tank if you bought it new.

Here is a video:

Sheet and long board storage

I’ve been collecting sheets of material. Acrylic sheets, plywood, insulating foam, etc. Currently the garage doesn’t have any place good to store large sheets of material, so I decided to build something up in the attic.

I started with two upright boards (made from scrap wood I had laying around).

Continue reading

Why you should NOT buy FOSCAM cameras

I used to own two FOSCAM cameras, which used to (mostly) work with Linux. They would ask you to install a proprietary plugin (that doesn’t work in Linux) to view their camera feed, but if you selected the MJPEG feed everything would still work with Linux or other OS’s without installing the plugin. (And you could manage them via the web interface with no problems.)

HOWEVER, after their latest firmware upgrade, their web management interface will NOT allow you to log in unless their proprietary plugins are detected. This means that you can not manage them from Linux. I asked them for a way to downgrade the firmware and they refused.

These cameras are now useless for use with Linux, and they are also useless unless you are willing to install foscam’s proprietary software on our (windows/mac) system. And if you trust FOSCAM to put code on your computer, you should read this: Bug Exposes IP Cameras, Baby Monitors or look here: Foscam : Security Vulnerabilities and reconsider letting them install software on your computers.

And then there are things like this:This is Why People Fear the “˜Internet of Things’

Shoe organizing bench from hardware store parts

Every so often a project of mine gets picked up by websites like Hackaday. This one is more likely to be collected on pinterest (that’s where the inspiration came from, my wife showed me a picture, and off I went).

Continue reading